QC12K Swing Beam Shearing Machine

Our swing beam type shears are the pacesetters in the current market, providing a high-quality and cost-effective solution for cutting full-length and extra-wide sheets. Equipped with the latest technology, our QC12 series shears boast a power rake angle adjustment function to ensure precision and accuracy in every cut.

Work Samples

- Carbon Steel

- Stainless Steel

- Brass

- Aluminum

- Galvanized Steel

Machine Features

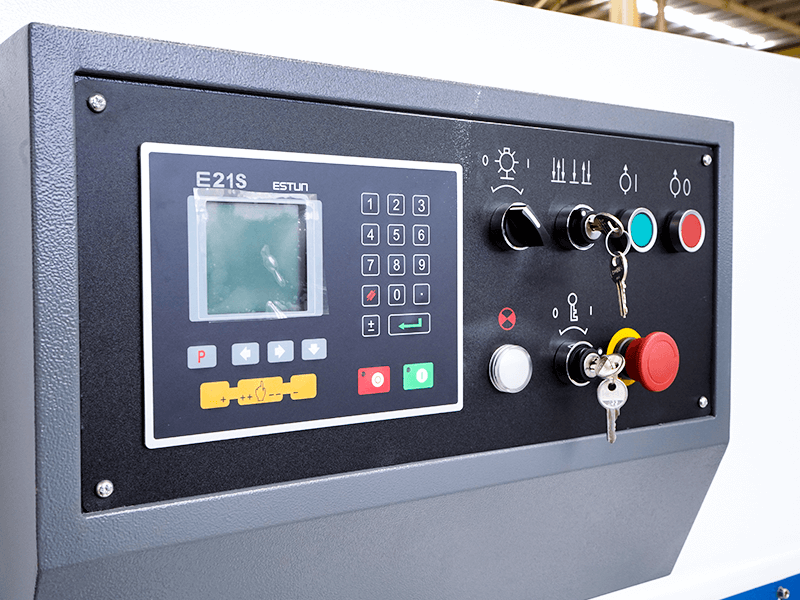

CNC Controller

Our plate shearing machine utilizes a specially designed, cost-effective numerical control system. We offer the option to include the DAC310T system from Delem, a renowned company in the Netherlands. This system is capable of automatically controlling the cutting angle and blade clearance for optimal performance.

Motor

As is widely recognized, servo motors have emerged as the dominant technology, aimed at achieving high dynamics and improving machine production efficiency with low energy consumption. Compared to traditional motors, the adoption of servo motors can lead to energy savings of up to 35%, thereby providing customers with the benefits of increased efficiency and reduced operating costs.

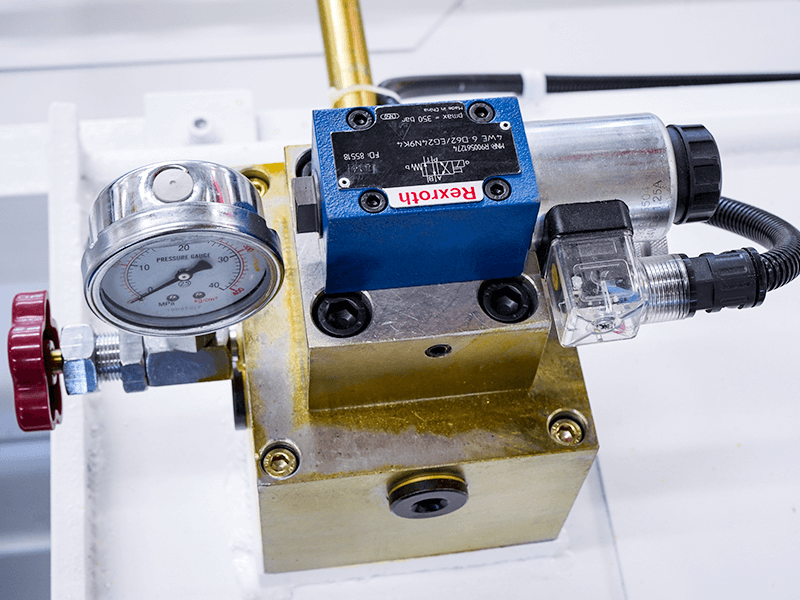

Hydraulic System

This hydraulic control system utilizes an electro-hydraulic servo and synchronous design with minimal spacing between hydraulic cylinders. It boasts robust anti-eccentric load capabilities, high accuracy synchronization, and an impressive power density ratio, all at a low cost.

Electrical Parts

The equipment employs authentic Schneider components imported from France, renowned for their stability, durability, and extended service life.

Feeding Port

Our machine offers a minimum feeding height that is equal to the sheet thickness, and a maximum feeding height that is equal to the sheet thickness plus 20-25mm. Adjustable height screws are also provided to allow for easy customization of the feeding height.

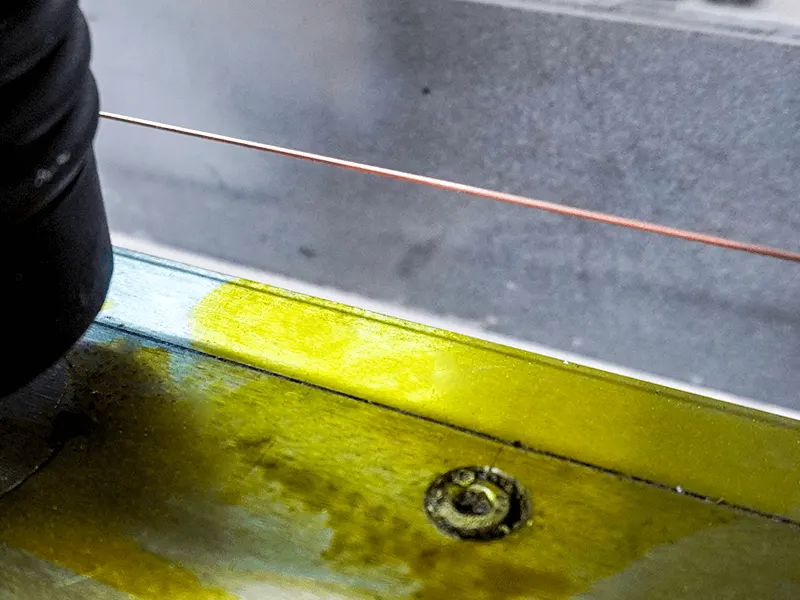

Cutting Line Illumination

The standard alignment device utilizes machine light to project a line shadow onto the sheet, achieving high cutting straightness and replacing traditional line drawing cutting methods.

Backgauge

The heavy-duty backgauge design ensures collision resistance of the back stopper and is less prone to deformation.

Hydraulic Oil Cooling Device

The machine can be used continuously for longer periods in high temperature environments.